What is Rudder Drop ?

Rudder Drop refers to the wear or downward shift of the rudder carrier’s bearing on a ship. As the bearing wears down, the rudder may lower, which can be measured to track the wear over time.

Must Read : Propeller Drop

How is Rudder Drop Measured?

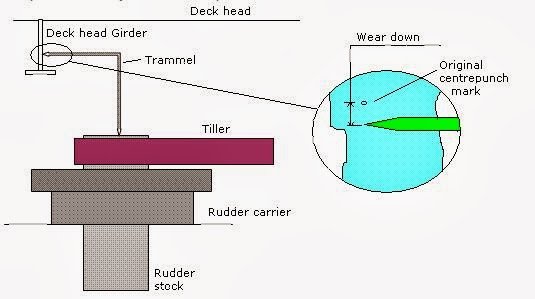

Rudder drop is typically measured using a Trammel Gauge, which is an L-shaped instrument. The process involves:

- Marking Reference Points: A point is marked on the rudder stock, and another point is marked on the hull, usually within the steering gear room (on the Deck head girder).

- Initial Measurement: The distance between these two points is measured and recorded during the ship’s construction.

- Subsequent Measurements: Over time, the same distance is measured. The difference between the original measurement and the current measurement indicates the rudder drop or the extent of bearing wear.

Rudder Clearance and Jumping Clearance

Rudder clearance refers to the space between the rudder and hull. Pads are welded to both components, and this clearance allows for movement and wear. Over time, as the carrier wears down, this clearance, also known as jumping clearance, will increase.

Why is Jumping Clearance Necessary?

Jumping clearance is essential to prevent damage to the steering gear. The clearance ensures that excessive wear does not impact the functionality of the steering system. If this clearance increases significantly, it may indicate excessive wear on the rudder carrier bearing.

Steering Clearance

Steering clearance is the gap between the steering gear and the rudder assembly. Monitoring this clearance is crucial because as the carrier wears down, this gap will shrink, and any significant reduction could affect the overall steering performance of the ship.

In summary, rudder drop, jumping clearance, and steering clearance are all important factors to monitor to ensure the proper functioning and safety of the ship’s steering system.

How a Trammel Gauge Works:

A trammel gauge is a simple yet effective instrument used to measure the distance between two fixed points, typically on large structures like a ship’s rudder system. Here’s a breakdown of how it works:

- Structure of the Gauge:

The trammel gauge is L-shaped, allowing for easy alignment with the two reference points. It has two adjustable pointers or arms that can be positioned to mark the distance between the points being measured. - Reference Points:

- One point is marked on the rudder stock (the vertical shaft connected to the rudder).

- The other point is marked on the hull, typically in the steering gear room, on the Deck head girder.

- Initial Measurement:

When the ship is constructed, the distance between these two points is measured and recorded using the trammel gauge. This serves as the baseline measurement for the rudder system. - Subsequent Measurements:

As the ship is used, wear and tear in the rudder bearing can cause the rudder to “drop” slightly. At regular intervals, the trammel gauge is used again to measure the distance between the same two points. - Rudder Drop Calculation:

The difference between the original distance (measured during construction) and the current distance (measured during inspection) is called the rudder drop or rudder wear down. This indicates how much the rudder bearing has worn down over time.

By comparing the two measurements, engineers can assess the wear on the rudder’s bearing and determine if maintenance or repairs are needed.