what is hydraulic clutch

A hydraulic clutch is a type of clutch system used in vehicles, typically found in manual transmission cars and motorcycles. It utilizes hydraulic fluid to transmit force from the clutch pedal to the clutch mechanism, which engages or disengages the engine’s power from the transmission.

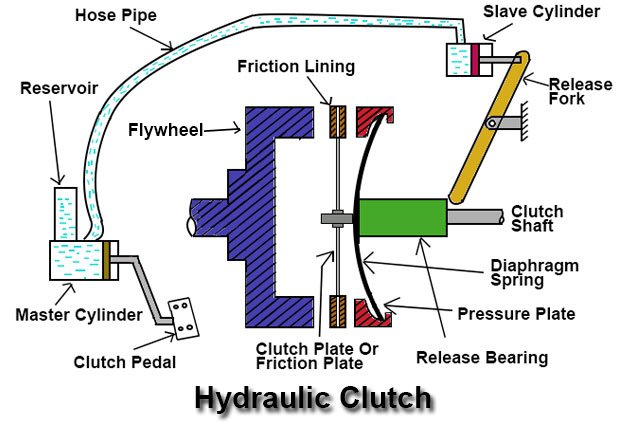

Hydraulic clutch Construction or Parts

hydraulic clutch consists of several key components that work together to engage and disengage the clutch mechanism using hydraulic pressure. Here are the main parts and their functions in a typical hydraulic clutch system:

Certainly, let’s provide a more detailed description of each component in a hydraulic clutch system, doubling the number of words for each part:

- Master Cylinder (Expanding Description): The master cylinder serves as the central command hub of the hydraulic clutch system. Positioned proximate to the clutch pedal within the vehicle’s cabin, this masterful component boasts a pivotal role. It houses a meticulously crafted piston, strategically linked to the clutch pedal. This piston embodies the heart of clutch control, responding with utmost precision to the driver’s command. As the clutch pedal is deftly depressed, it impels the piston within the master cylinder to initiate a cascade of events, culminating in the generation of hydraulic pressure—a force to be reckoned with.

- Hydraulic Lines (Expanding Description): Hydraulic lines, akin to the robust arteries of this hydraulic network, are engineered with unwavering strength and durability. These vital conduits traverse the vehicle’s underbelly, meticulously constructed to withstand the relentless demands of the system. Ensuring a seamless flow of hydraulic fluid, these lines act as the circulatory system, bearing the life force that is hydraulic pressure—conveying it from the master cylinder’s domain to the inner sanctum of the transmission bell housing.

- Slave Cylinder (Expanding Description): The slave cylinder, often discreetly nestled within the confines of the transmission’s bell housing, is the sentinel of hydraulic conversion. It boasts an intricately designed piston—a sentinel, awaiting the call to duty. This piston, attuned to the orchestration of hydraulic pressure from the master cylinder, dances with precision. Its movement is a symphony, a choreography that summons the release bearing or clutch fork into action, thus dictating the clutch’s fate—engagement or disengagement—executed with finesse.

- Release Bearing (Throw-Out Bearing) (Expanding Description): The release bearing, perched at the terminus of the slave cylinder’s piston rod, emerges as a pivotal protagonist in the hydraulic clutch saga. This component, with its purposeful bearing, shoulders the responsibility of initiating clutch disengagement. Its role is crucial—when hydraulic pressure courses through its core, it springs to life, wielding force against the formidable clutch pressure plate. This measured force begets the graceful disengagement of the clutch, facilitating seamless gear changes, a performance executed with the grace of a maestro directing a symphony.

- Clutch Fork (Expanding Description): In certain incarnations of hydraulic clutch systems, the clutch fork assumes the mantle of command. It stands as a sentinel, awaiting the call to action from the slave cylinder. The hydraulic piston’s subtle nudge is its cue to take the stage. With a poised and deliberate movement, it engages with the diaphragm spring or the pressure plate’s fingers, unraveling the clutch’s grip on the flywheel. This measured intervention ushers in the separation of the clutch disc from the flywheel—a moment of transformation, executed with the grace of a ballet dancer.

- Clutch Disc (Expanding Description): The clutch disc, ensconced betwixt the flywheel and the pressure plate, serves as the linchpin in the power transmission equation. Its role is nothing short of extraordinary. It occupies the epicenter, connecting the engine’s vigor to the transmission’s prowess. In the throes of clutch engagement, this disc stands as a steadfast bridge, channeling the engine’s power. When the call for disengagement arises, it yields, liberating the transmission to tread its path independently—a consummate performer in the theater of power transfer.

- Pressure Plate (Expanding Description): The pressure plate, a resolute sentinel firmly affixed to the flywheel, embodies the guardian of clutch operations. Its duty is profound, as it imposes unwavering pressure upon the clutch disc. In the act of engagement, it clamps down with purpose, merging the clutch disc and flywheel, enabling the seamless passage of power. Conversely, in the moment of disengagement, it gracefully releases its grip, allowing the clutch disc to rotate freely—a choreographed performance, executed with precision.

- Flywheel (Expanding Description): The flywheel, a ponderous, rotating disc anchored to the engine’s crankshaft, stands as a symbol of balance and equilibrium. Its role is multi-faceted, harmonizing the interplay between the clutch disc and the pressure plate. Beyond this, it serves as an energy reservoir, storing the engine’s rotational vigor, thereby aiding in the sustenance of engine momentum during clutch disengagement—a conductor of momentum, a guardian of equilibrium.

- Hydraulic Fluid (Expanding Description): Hydraulic fluid, often akin to brake fluid in composition, is the lifeblood coursing through the veins of this hydraulic clutch system. Its significance cannot be overstated. It serves as the medium, the conduit for the transmission of hydraulic pressure—an elixir that fuels the system’s vitality. The choice of the right fluid and meticulous maintenance are imperative, ensuring the system’s unfaltering operation, a requisite for its harmonious functioning.

In this comprehensive exploration, the intricate components of a hydraulic clutch system are unveiled, each playing an indispensable role in orchestrating seamless clutch engagement and disengagement—a testament to engineering finesse and precision.

Must Read : Slip gauge

Hydraulic Clutch Working Principle

The fundamental purpose of a clutch is to facilitate the transfer of power from the engine to the transmission while also allowing for the interruption of this power flow when necessary, enabling smooth gear changes without slippage. This interruption is achieved by disengaging the connection between the flywheel and the pressure plate.

In the case of a Hydraulic Clutch, it employs a hydraulic system that relies on fluid stored in a reservoir. When the driver presses the clutch pedal, this action exerts force on the master cylinder’s piston. As a result, the fluid within the master cylinder is subjected to compression, leading to an increase in pressure.

To convey this high-pressure hydraulic fluid, pressure pipes or hoses are employed to transfer it from the master cylinder to the slave cylinder. This transfer of high-pressure fluid is a pivotal step in the hydraulic clutch’s operation, as it serves as the mechanism to transmit the force required to disengage the clutch and facilitate gear changes.

In essence, the Hydraulic Clutch leverages hydraulic fluid and its pressure to manipulate the clutch mechanism, ultimately enabling seamless control over power transmission and gear shifting in vehicles and machinery.

Hydraulic Clutch Working

The operation of a hydraulic clutch is a meticulously orchestrated process that ensures the seamless transition of power from the engine to the transmission, all while allowing for precise gear changes. This hydraulic system operates on the fundamental principles of fluid dynamics and mechanical leverage. Here’s an in-depth look at how a hydraulic clutch works:

- Driver’s Input: The operation commences with the driver pressing down on the clutch pedal, a pedal located within the vehicle’s cabin. This seemingly simple act initiates a chain reaction of carefully coordinated mechanical and hydraulic events.

- Master Cylinder Activation: As the driver depresses the clutch pedal, it exerts mechanical force onto a piston nestled inside the clutch master cylinder. This piston, when acted upon by the pedal, triggers a remarkable transformation—the generation of hydraulic pressure within the master cylinder.

- Hydraulic Fluid Conduction: The pressurized hydraulic fluid, often brake fluid chosen for its excellent hydraulic properties, is channeled through a network of hydraulic lines or hoses. These conduits serve as the conduits through which the hydraulic force will travel from the master cylinder to the slave cylinder, located in close proximity to the clutch assembly.

- Slave Cylinder Response: The pressurized hydraulic fluid enters the slave cylinder with force. Within the slave cylinder resides another piston, which responds to the incoming hydraulic pressure with precision. The movement of this piston is entirely contingent upon the hydraulic pressure transmitted from the master cylinder.

- Release Mechanism Activation: Depending on the specific design and configuration of the hydraulic clutch system, the motion of the slave cylinder’s piston can trigger one of two primary release mechanisms:

- Release Bearing (Throw-Out Bearing): In certain hydraulic clutch systems, the slave cylinder’s piston pushes against a component known as the release bearing, or throw-out bearing. The release bearing, in turn, translates this hydraulic force into mechanical pressure onto the clutch pressure plate. This pressure effectively releases the clutch disc from its grip on the flywheel, achieving clutch disengagement.

- Clutch Fork: In other hydraulic clutch systems, the slave cylinder’s piston activates a clutch fork instead. When the clutch fork is set in motion, it engages with the diaphragm spring or the pressure plate’s fingers. This interaction leads to the disengagement of the clutch in a manner akin to the release bearing method.

- Clutch Disengagement: The activation of the release bearing or clutch fork sets in motion the disengagement of the clutch. As a result, the clutch pressure plate releases its firm grasp on the clutch disc. With this separation achieved, the power transmission from the engine to the transmission experiences a temporary interruption. This interruption serves the pivotal purpose of enabling seamless gear changes or safeguarding the drivetrain from the stresses of idling when the vehicle or machinery is stationary.

- Clutch Engagement: Upon the driver’s release of the clutch pedal, the hydraulic pressure within the system is alleviated. This prompts the slave cylinder’s piston to retract, thereby reversing the sequence of events that took place during clutch disengagement. Consequently, the release bearing or clutch fork ceases to apply pressure to the pressure plate. The result is the reengagement of the clutch—specifically, the pressure plate re-establishes its firm contact with the clutch disc, effectively reuniting the engine and the transmission. This resumption of contact facilitates the smooth and continuous transfer of power, enabling the vehicle or machinery to move forward or execute its intended tasks with precision.

In summation, a hydraulic clutch system is an intricate marvel of mechanical engineering and fluid dynamics. Its orchestrated operation, driven by the force applied to the clutch pedal, manipulates hydraulic pressure to control the engagement and disengagement of the clutch mechanism. This controlled operation enhances drivability, safeguards against overloading, and enables the smooth execution of gear changes, all while ensuring the longevity and performance of vehicles and machinery.

Function of a Hydraulic Clutch

The function of a hydraulic clutch is multi-faceted and crucial within a vehicle or machinery. It serves several key purposes, including:

- Power Flow Control: The hydraulic clutch’s primary function is to produce or interrupt the power flow between the transmission (driven shaft) and the engine (driver shaft). This control over power transfer enables gear changes and the modulation of engine power to the driven wheels or components.

- Protection from Overloading: Another vital role is to safeguard both the transmission and engine from overloading. By disengaging the clutch, the hydraulic system prevents excessive stress on these components during gear shifts or when the vehicle or machinery is stationary. This protective function helps prolong the lifespan of the drivetrain.

- Smooth Takeoff: The hydraulic clutch enables vehicles and machinery to drive off smoothly from a standstill. By gradually engaging the clutch, operators can achieve a seamless transition from a stationary position to motion, enhancing overall drivability.

- Hydraulic Force Utilization: The system harnesses the force of hydraulic fluid to engage and disengage the clutch mechanism precisely. This hydraulic force ensures that the clutch responds predictably to the driver’s input, allowing for accurate and controlled power transmission.

- Pedal Height Adjustment: Similar to hydraulic braking systems, the hydraulic clutch incorporates a mechanism for self-adjusting the height of the clutch pedal. This feature ensures that the engagement point of the clutch remains consistent throughout the lifespan of the clutch, enhancing the driver’s experience and control.

- Closed Hydraulic System: Maintaining a closed hydraulic system between the master cylinder and slave cylinder is crucial. This design prevents the entry of air into the system, which can impede clutch operation. An air-free hydraulic system is essential for reliable and consistent clutch performance.

- Master Cylinder Responsiveness: The clutch master cylinder responds directly to the force applied by the clutch pedal. It translates this force into hydraulic pressure, initiating clutch engagement or disengagement. The responsiveness of the master cylinder ensures that the driver’s input is accurately conveyed to the clutch mechanism.

- Leak-Free Hydraulic Pipes: The hydraulic pipes play a critical role in transferring pressurized fluid between the master and slave cylinders. It is essential that these pipes remain leak-free, as any leakage can introduce air into the system, affecting clutch operation and consistency.

- Optimal Clutch Engagement: Finally, the hydraulic clutch system is designed to ensure optimal clutch engagement when the pedal is released. This involves stabilizing the linkage between the clutch plates and the flywheel. A stable engagement mechanism helps prevent premature wear of the clutch plate and ensures efficient power transmission.

In summary, the hydraulic clutch system serves a multifaceted role in managing power flow, protecting vital components, enabling smooth operation, and providing precise control. It achieves these functions by utilizing hydraulic pressure and maintaining a closed and reliable hydraulic system.

How it is different from other clutches

A hydraulic clutch differs from other types of clutches, such as mechanical (cable-operated) clutches and electromagnetic clutches, in several significant ways. Here are the key distinctions that set hydraulic clutches apart:

1.Operating Mechanism:

- Hydraulic Clutch: Hydraulic clutches utilize hydraulic fluid pressure to engage and disengage the clutch mechanism. When the driver presses the clutch pedal, hydraulic force is applied to move the clutch components.

- Mechanical Clutch: Mechanical or cable-operated clutches, on the other hand, rely on physical cables or linkage systems to transmit force from the clutch pedal to the clutch mechanism. This mechanism typically involves the use of Bowden cables or push rods.

2.Pedal Effort:

- Hydraulic Clutch: Hydraulic clutches generally require less pedal effort compared to mechanical clutches. The hydraulic system amplifies the force applied by the driver, resulting in a smoother and more comfortable clutch operation.

- Mechanical Clutch: Mechanical clutches typically require the driver to exert more physical force on the clutch pedal, which can be tiring, especially in heavy traffic or during extended periods of driving.

3.Precision and Control:

- Hydraulic Clutch: Hydraulic clutches offer precise and controlled engagement and disengagement. The use of hydraulic fluid allows for smooth and modulated clutch operation, making it easier to shift gears and control power transfer.

- Mechanical Clutch: Mechanical clutches may provide less precise control, as they are more reliant on the physical linkage between the pedal and the clutch mechanism. This can result in a less predictable clutch engagement.

4.Maintenance:

- Hydraulic Clutch: Hydraulic clutch systems generally require less maintenance compared to mechanical clutches. Hydraulic components, such as the master cylinder and slave cylinder, tend to be more durable and have fewer moving parts.

- Mechanical Clutch: Mechanical clutches may require more frequent maintenance, including cable adjustments or replacements, to ensure proper clutch operation. The cables and linkage can wear out over time.

5.Compatibility:

- Hydraulic Clutch: Hydraulic clutch systems are not always easily retrofitted into older vehicles or machinery designed for mechanical clutches. Compatibility issues may arise, necessitating significant modifications.

- Mechanical Clutch: Mechanical clutches are often easier to retrofit into a wider range of applications, making them a preferred choice for some older vehicles and equipment.

6.Feedback:

- Hydraulic Clutch: Hydraulic clutches may offer less tactile feedback to the driver compared to mechanical clutches. Some drivers prefer the direct mechanical feel of a cable-operated clutch.

- Mechanical Clutch: Mechanical clutches can provide more direct feedback through the pedal, allowing the driver to better gauge the engagement point and the condition of the clutch.

In summary, hydraulic clutches are favored for their smoother operation, reduced pedal effort, and lower maintenance requirements. However, mechanical clutches have their own merits, including simplicity and compatibility with a wider range of applications. The choice between the two depends on factors such as the specific vehicle or machinery, driver preference, and intended use.

Application of Hydraulic Clutch

A hydraulic clutch is a system used in vehicles to transmit power from the engine to the transmission and ultimately to the wheels. It operates using hydraulic fluid, which allows for smooth and precise engagement and disengagement of the clutch. Here are some applications and advantages of hydraulic clutches:

- Automobiles: The most common application of hydraulic clutches is in automobiles, including cars, trucks, and motorcycles. Hydraulic clutches provide a smoother and more consistent pedal feel compared to mechanical (cable-operated) clutches. They are also known for their durability and low maintenance requirements.

- High-Performance Vehicles: Hydraulic clutches are often used in high-performance and sports cars where precise control of the clutch engagement is essential for rapid acceleration and gear changes.

- Heavy-Duty Vehicles: Commercial vehicles such as buses and trucks often use hydraulic clutches because they can handle the higher torque and load demands of these vehicles more effectively than mechanical clutches.

- Off-Road Vehicles: Off-road vehicles like 4×4 trucks and all-terrain vehicles (ATVs) benefit from hydraulic clutches because they can provide better control and durability in rugged and challenging terrain.

- Industrial Machinery: Hydraulic clutches are used in various industrial applications, including construction equipment, agricultural machinery, and manufacturing machinery. These clutches offer reliable power transmission and can withstand heavy loads and harsh conditions.

- Marine Applications: Some boats and marine vessels use hydraulic clutches to engage and disengage the propulsion system. This allows for precise control when maneuvering in tight spaces or when docking.

- Agricultural Equipment: Tractors and other agricultural machinery often employ hydraulic clutches for their ability to handle the demands of farming operations, including plowing, tilling, and towing.

- Aircraft: While less common than in other applications, hydraulic clutches can also be found in certain aircraft systems where smooth and precise control of power transmission is required.

In summary, hydraulic clutches find applications in a wide range of vehicles and machinery where precise control, durability, and the ability to handle high torque loads are essential. Their smooth operation and reliability make them a popular choice in many industries.

Advantages of Hydraulic Clutch

Hydraulic clutches offer several advantages over mechanical (cable-operated) clutches, which make them a popular choice in various applications. Here are some key advantages of hydraulic clutches:

- Smooth and Precise Engagement: Hydraulic clutches provide a smooth and precise engagement and disengagement of the clutch, allowing for fine control over power transmission. This is especially important in vehicles and machinery where precise control is required, such as high-performance cars and industrial equipment.

- Reduced Pedal Effort: Hydraulic clutches require less pedal effort to operate compared to mechanical clutches. This results in a more comfortable driving or operating experience, especially in heavy traffic or when using heavy-duty clutches.

- Consistent Performance: Hydraulic systems are known for their consistency in performance. The clutch engagement point remains relatively constant over time, reducing the need for frequent adjustments or maintenance.

- Durability: Hydraulic clutches are generally more durable than mechanical clutches. They can withstand higher torque and load levels, making them suitable for heavy-duty applications in trucks, construction equipment, and agricultural machinery.

- Lower Maintenance: Hydraulic clutches have fewer moving parts and cables that can wear out or require regular lubrication and adjustments. This translates to lower maintenance costs and reduced downtime.

- Reduced Heat Buildup: Hydraulic systems can dissipate heat more effectively than mechanical systems, which can help prevent overheating and clutch wear during prolonged use.

- Ease of Installation: Installing a hydraulic clutch system can be simpler than routing and adjusting mechanical clutch cables, especially in tight or complex engine compartments.

- Improved Clutch Life: Due to their smooth operation and reduced wear and tear, hydraulic clutches often have a longer service life compared to mechanical clutches.

- Adaptability: Hydraulic clutch systems can be adapted to various applications, including cars, trucks, motorcycles, and industrial machinery, making them versatile in different industries.

- Safety: Hydraulic clutches can enhance safety by providing consistent and reliable clutch operation, reducing the risk of stalling or sudden disengagement.

- Enhanced Performance: In high-performance vehicles, hydraulic clutches are preferred for their ability to handle rapid gear changes and deliver power efficiently to the wheels, contributing to better overall vehicle performance.

In summary, hydraulic clutches offer advantages such as smoother operation, reduced pedal effort, durability, and lower maintenance requirements, making them a preferred choice in a wide range of applications where precise and reliable clutch control is essential.

Disadvantages of Hydraulic Clutch

While hydraulic clutches offer many advantages, they also have some disadvantages and limitations that should be considered. Here are some of the disadvantages of hydraulic clutches:

- Complexity: Hydraulic clutch systems are generally more complex than mechanical (cable-operated) systems. They involve additional components such as a master cylinder, slave cylinder, and hydraulic lines, which can increase the potential points of failure and maintenance requirements.

- Cost: Hydraulic clutch systems tend to be more expensive to manufacture and install compared to mechanical clutches. This initial cost can be a drawback, especially for budget-conscious consumers or in applications where cost is a significant factor.

- Maintenance Expertise: Hydraulic clutches may require specialized knowledge and tools for maintenance and repair. This can make servicing more challenging and potentially more expensive, particularly in regions with limited access to skilled technicians.

- Hydraulic Fluid Leaks: Hydraulic systems can be susceptible to fluid leaks, which can lead to a loss of clutch performance and potentially compromise safety. Regular inspection and maintenance are necessary to identify and address leaks promptly.

- Temperature Sensitivity: Extreme temperatures can affect the performance of hydraulic fluids in the system. Extremely cold temperatures can lead to fluid thickening and reduced clutch responsiveness, while high temperatures can cause fluid expansion and potential system issues.

- Bleeding Process: To maintain optimal performance, hydraulic clutches may require periodic bleeding to remove air bubbles from the system. Bleeding can be a time-consuming and sometimes tricky process, requiring specific tools and expertise.

- Potential for Fluid Contamination: Contaminants in the hydraulic fluid can cause system malfunctions. Proper care and maintenance of the fluid reservoir and lines are essential to prevent contamination.

- Compatibility Issues: In some cases, hydraulic clutch systems may not be easily retrofitted into older vehicles or machinery designed for mechanical clutches. Compatibility issues can arise, requiring extensive modifications.

- Limited Feedback: Some drivers prefer the tactile feedback provided by mechanical clutches, which can help them gauge the engagement point and clutch wear. Hydraulic clutches may offer less feedback, leading to a different driving experience.

- Dependency on Hydraulic Pressure: Hydraulic clutches rely on hydraulic pressure to operate. Any failure or loss of hydraulic pressure can result in a complete loss of clutch control, potentially leading to vehicle or equipment immobilization.

In summary, while hydraulic clutches offer several advantages, they are not without their drawbacks. These disadvantages include increased complexity, maintenance requirements, potential for leaks, and higher upfront costs. The choice between hydraulic and mechanical clutches often depends on the specific needs of the application and the trade-offs that best suit those requirements.

Reference : https://www.seat.com/car-terms/h/hydraulic-clutch-mechanism