what is hydraulic system

A hydraulic system is a technology that utilizes pressurized fluid to generate, transmit, control, and distribute power. It is commonly used in a variety of applications where high force or precise control is needed, such as in heavy machinery, construction equipment, automotive systems, aircraft controls, and industrial machinery.

Must Read : Corrosion Inhibitor

hydraulic system parts

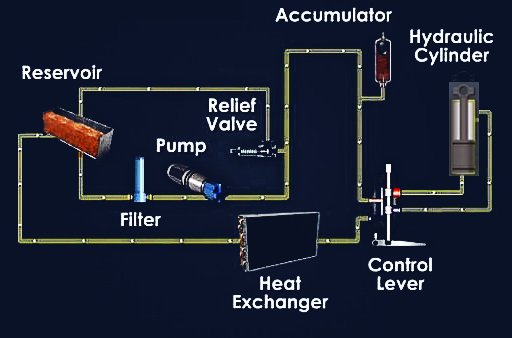

Certainly, I can expand on the topic. Here’s a more detailed explanation of each component of a hydraulic system:

- Reservoir (Fluid Tank): The reservoir, often referred to as a fluid tank or hydraulic tank, is a container that holds the hydraulic fluid used in the system. Its design includes features to prevent contamination and provide space for air separation. The reservoir’s capacity is chosen based on the system’s fluid volume requirements and cooling needs. It’s equipped with an inlet filter to prevent contaminants from entering the system and an outlet filter to maintain fluid cleanliness. A breather cap allows air exchange while preventing dirt and moisture from entering.

- Hydraulic Pump: The hydraulic pump is the heart of the system. It draws hydraulic fluid from the reservoir and converts mechanical power (usually from an engine or motor) into hydraulic power. The pump creates pressure by generating flow, which pressurizes the fluid and propels it through the system. Different pump types offer varying levels of efficiency, flow rates, and pressure capabilities to match specific application requirements.

- Hydraulic Fluid: Hydraulic fluid serves as the medium for transmitting power within the system. It must possess excellent lubricating properties to minimize wear and friction between moving components. The fluid’s viscosity is carefully selected based on the temperature range the system will operate in. Additionally, hydraulic fluids should resist foaming and oxidation to maintain their performance over time.

- Filters: Filters are integral to maintaining hydraulic fluid cleanliness. Suction filters are positioned at the pump inlet to capture large contaminants that could damage the pump. Pressure filters are located downstream to remove smaller particles and ensure fluid purity. Regular filter replacement or cleaning is vital to prevent clogs and maintain system efficiency.

- Valves: Valves control the flow and pressure of hydraulic fluid throughout the system. Control valves regulate the fluid flow rate to actuators, allowing precise control of motion. Directional control valves dictate the direction of fluid flow to achieve desired movement. Pressure control valves maintain system pressure within safe limits, and flow control valves regulate the speed of actuators to match specific requirements.

- Actuators: Actuators convert hydraulic pressure into mechanical motion. Hydraulic cylinders consist of a cylinder barrel, piston, and rod. When hydraulic pressure is applied to one side of the piston, it creates linear motion, which is used for lifting, pushing, or pulling. Hydraulic motors produce rotational motion by converting hydraulic pressure into torque, serving applications that require rotational force.

- Pipes and Hoses: Pipes and hoses transport hydraulic fluid between different components of the system. Pipes are used for rigid connections, while hoses allow flexibility and movement between components. Proper sizing and material selection are critical to handle fluid pressure and flow while preventing leakage.

- Accumulators: Accumulators store hydraulic energy in the form of compressed fluid. They can release stored energy quickly to provide additional power when required or absorb shocks to protect the system. Accumulators help maintain system stability, enhance response times, and act as emergency power sources during pump failure.

- Pressure Relief Valves: Pressure relief valves are safety devices that protect the system from excessive pressure. When pressure surpasses a predetermined threshold, these valves open to release excess fluid, preventing damage to components and preserving system integrity.

- Seals and Gaskets: Seals and gaskets prevent hydraulic fluid from leaking at various points within the system. These components ensure that the hydraulic fluid remains contained, preventing environmental contamination and maintaining efficient operation.

- Coolers and Heat Exchangers: Hydraulic systems generate heat during operation due to fluid friction and pressure changes. Coolers and heat exchangers dissipate this heat to prevent fluid overheating, ensuring consistent fluid viscosity and component longevity.

- Fittings and Connectors: Fittings and connectors are essential for joining pipes, hoses, and other components together. These connections must be leak-free and secure to maintain fluid flow integrity.

- Gauges and Sensors: Gauges and sensors provide operators with crucial information about the system’s status and performance. Pressure gauges measure hydraulic pressure, temperature sensors monitor fluid temperature, and fluid level sensors indicate the fluid level within the reservoir.

- Control Devices: Control devices enable operators to manipulate the hydraulic system. Joysticks, pedals, levers, and switches are commonly used to command the movement and operation of hydraulic actuators.

A properly designed and maintained hydraulic system involves the careful selection and integration of these components to ensure reliable, efficient, and safe operation for a wide range of applications.

hydraulic system working

A hydraulic system functions based on the principles of Pascal’s law, which dictates that changes in pressure applied to a confined fluid are uniformly transmitted throughout that fluid. This core principle enables hydraulic systems to leverage fluid pressure for a range of tasks. The process starts with a reservoir where hydraulic fluid, often hydraulic oil for its lubricating and heat-absorbing properties, is stored. An external power source, such as an electric motor or internal combustion engine, drives a hydraulic pump. This pump draws fluid from the reservoir and pushes it into the system, elevating its pressure. The pressurized hydraulic fluid then flows through pipes and hoses, creating an energy flow. This flow generates pressure, which translates to force applied to the walls of these conduits.

Control valves play a pivotal role in regulating fluid flow to different components. By manipulating these valves, operators can direct the fluid to specific actuators, enabling precise control over the system’s actions. These actuators, commonly hydraulic cylinders and hydraulic motors, convert the pressurized fluid’s energy into mechanical motion. Hydraulic cylinders are responsible for linear motion, wherein fluid pressure pushes a piston, extending a rod and producing linear movement. On the other hand, hydraulic motors provide rotational motion by converting fluid pressure into torque, thus enabling rotational force.

The pressure generated by the pump is uniformly transmitted throughout the hydraulic fluid, ensuring that force is evenly distributed. After performing the intended tasks, the hydraulic fluid returns to the reservoir or designated return line, completing its circuit within the system. To manage the heat generated due to fluid friction and pressure fluctuations, cooling systems and heat exchangers are employed. Filters are integrated to remove contaminants from the fluid, preserving its cleanliness and preventing damage to system components. Pressure relief valves act as safety measures by releasing excessive pressure, thus averting potential damage.

In modern hydraulic systems, electronic controls, sensors, and feedback mechanisms are often integrated, allowing for precise and automated management. This technological advancement enhances both efficiency and safety. Hydraulic systems find diverse applications across industries, offering substantial force, precise control, and efficient power transmission. Their adaptability spans from heavy construction machinery to intricate manufacturing processes, making them a cornerstone of contemporary industrial operations.

application of hydraulic system

Hydraulic systems are used in a wide range of applications across various industries due to their ability to generate high forces, precise control, and efficient power transmission. Here are some common applications of hydraulic systems:

- Construction Machinery: It is extensively used in construction equipment such as excavators, bulldozers, loaders, cranes, and backhoes. These machines rely on hydraulic power for lifting heavy loads, digging, pushing, and precise positioning.

- Agricultural Equipment: Tractors, combines, and other agricultural machinery often use hydraulic systems to power implements like plows, harrows, and loaders. Hydraulic systems provide the force needed for various tasks in farming.

- Aircraft Control: It play a critical role in controlling the movement of aircraft components such as landing gear, flaps, and ailerons. They provide the necessary force to handle the aerodynamic forces on the aircraft.

- Automotive Industry: In automobiles, It is used in brake systems (hydraulic brakes), power steering systems, suspension systems, and convertible tops.

- Industrial Machinery: Hydraulic systems are found in industrial machinery like presses, stamping machines, injection molding machines, and hydraulic presses. They provide the force required for shaping, bending, and forming materials.

- Material Handling: Forklifts and other material handling equipment use hydraulic systems to lift and move heavy loads efficiently.

- Mining Equipment: It is used in mining machinery for tasks such as drilling, crushing, and transporting materials.

- Marine Applications: It is used in ships and boats for steering mechanisms, anchor handling, and cargo handling.

- Oil and Gas Industry: It is used in drilling rigs, offshore platforms, and various equipment for extracting, transporting, and processing oil and gas.

- Heavy Machinery: Hydraulic systems are crucial in heavy machinery used in industries like logging, forestry, and waste management.

- Railroad Equipment: Hydraulic systems are used in railroad maintenance equipment for tasks such as track maintenance and repair.

- Hydraulic Elevators: Elevators that use hydraulic systems are common in low-rise buildings. The hydraulic fluid is used to lift the elevator car.

- Hydraulic Presses: Hydraulic presses are used in manufacturing processes to shape, form, and compress materials. They are essential in industries like metalworking and rubber processing.

- Waste Management Equipment: Garbage trucks and compactors often use hydraulic systems to efficiently collect and compact waste.

- Hydraulic Tools: Many tools such as jacks, crimpers, and cutters are powered by hydraulic systems for heavy-duty tasks.

These are just a few examples of the diverse applications of hydraulic systems. They are chosen for tasks where high force, precise control, and efficient power transmission are essential for optimal performance. However, as technology evolves, some applications are transitioning to more advanced alternatives like electric and electronic systems for improved efficiency and environmental considerations.

advantages of hydraulic system

Hydraulic systems offer several advantages that make them well-suited for a wide range of applications. Some of the key advantages of hydraulic systems include:

- High Force and Power: Hydraulic systems can generate extremely high forces, allowing them to lift heavy loads and perform tasks that require substantial power. This is particularly useful in applications such as construction, manufacturing, and heavy machinery.

- Precise Control: Hydraulic systems provide fine control over movement and force, making them suitable for tasks that require accurate positioning, speed control, and controlled acceleration and deceleration.

- Variable Speed and Force: By adjusting the flow of hydraulic fluid, operators can easily vary the speed and force of hydraulic actuators, providing flexibility in performing different tasks.

- Compact Design: Hydraulic components are relatively compact and can be arranged in tight spaces, making hydraulic systems suitable for applications where space is limited.

- Safety and Reliability: Hydraulic systems are known for their reliability, durability, and long service life. They can withstand heavy loads, shock loads, and demanding operating conditions. Additionally, hydraulic systems can be designed with fail-safe mechanisms to ensure safe operation.

- Smooth Operation: Hydraulic systems offer smooth and consistent motion, reducing wear and tear on components and improving the overall operational efficiency.

- Overload Protection: Pressure relief valves and overload protection mechanisms can be integrated into hydraulic systems to prevent damage caused by excessive pressure or force.

- Constant Force Output: Hydraulic systems maintain a relatively constant force output regardless of the load, which can be advantageous in applications where consistent force is required.

- Easily Transmit Power Over Long Distances: Hydraulic fluids are incompressible, allowing them to transmit power effectively over long distances through pipes and hoses without significant energy loss.

- Adaptability: Hydraulic systems can be customized and adapted to suit specific applications by adjusting parameters such as fluid pressure, flow rate, and component sizes.

- Ability to Work in Extreme Conditions: Hydraulic systems can operate in a wide range of temperatures and environmental conditions, from freezing cold to high heat.

- Maintenance and Troubleshooting: Hydraulic systems are generally easier to diagnose and repair due to their simple design and readily available components. Regular maintenance, including fluid replacement and filter changes, can extend the lifespan of the system.

- Cost-Effectiveness: Hydraulic systems are often more cost-effective to implement than other power transmission methods, especially for applications that require high force output.

- Remote Control: Hydraulic systems can be operated remotely using control valves and actuators, enabling operators to perform tasks from a safe distance.

- Versatility: Hydraulic systems can be used in a wide range of applications across various industries, from construction to aerospace, manufacturing to entertainment.

Despite these advantages, it’s important to note that hydraulic systems also have limitations and considerations, such as the need for proper maintenance, potential fluid leaks, and concerns about environmental impact. Additionally, advances in electric and electronic systems have led to competition with hydraulic systems in certain applications.

disadvantages of hydraulic system

While hydraulic systems offer numerous advantages, they also come with certain disadvantages and limitations that should be considered when choosing a power transmission method. Some of the disadvantages of hydraulic systems include:

- Fluid Leaks: Hydraulic systems can be prone to fluid leaks, which can lead to environmental contamination, safety hazards, and maintenance challenges. Regular inspection and maintenance are essential to prevent and address leaks.

- Maintenance Requirements: Hydraulic systems require regular maintenance, including fluid changes, filter replacements, and component inspections. Neglecting maintenance can lead to reduced system performance and increased downtime.

- Fluid Contamination: Contaminants in the hydraulic fluid, such as dirt, debris, and moisture, can lead to component wear, reduced efficiency, and decreased system lifespan. Effective filtration and proper fluid management are necessary to mitigate these issues.

- Fluid Compatibility: Selecting the right hydraulic fluid is crucial, as incompatible fluids can lead to damage to seals, hoses, and other components. Fluid selection should consider factors such as temperature, viscosity, and compatibility with materials.

- Temperature Sensitivity: Hydraulic systems can be sensitive to extreme temperatures. Cold temperatures can cause fluid thickening, resulting in reduced system performance, while high temperatures can lead to fluid degradation and decreased efficiency.

- Energy Efficiency: In some cases, hydraulic systems may be less energy-efficient compared to other power transmission methods, especially in situations where energy losses due to fluid friction and leaks are significant.

- Noise and Vibrations: Hydraulic systems can generate noise and vibrations during operation, which can be undesirable in certain applications, such as precision equipment or environments where noise is a concern.

- Complexity of Design: Designing and building hydraulic systems require specialized knowledge and expertise, especially when it comes to ensuring proper sizing, component selection, and integration. This complexity can lead to higher design and implementation costs.

- System Weight: Hydraulic systems can be relatively heavy due to the need for fluid reservoirs, pumps, and associated components. This can impact the overall weight and mobility of equipment and machinery.

- Environmental Impact: Hydraulic systems rely on hydraulic fluids, which can have environmental consequences if not managed properly. Fluid spills and leaks can lead to soil and water contamination.

- Limited Speed Control: While hydraulic systems offer precise control over force and position, achieving precise speed control can be more challenging. Rapid speed changes may require additional control mechanisms.

- Limited Response Time: Hydraulic systems may have a slower response time compared to electronic systems, which can affect applications that require rapid changes in force or position.

- Hydraulic Shock: Rapid changes in pressure or flow within a hydraulic system can result in hydraulic shock (water hammer), which can damage components and lead to system failure if not properly controlled.

- Heat Generation: Hydraulic systems generate heat during operation due to fluid friction and pressure changes. If not adequately managed, excessive heat can degrade fluid performance and damage components.

- Environmental Regulations: Increasing environmental regulations related to fluid disposal and leakage are prompting industries to consider alternatives to hydraulic systems to minimize ecological impact.

Despite these disadvantages, hydraulic systems remain a valuable technology in many applications. It’s essential to carefully assess the specific requirements of a given application and consider the advantages and disadvantages when deciding whether to use a hydraulic system or explore alternative power transmission methods like electric systems.

Reference : https://en.wikipedia.org/wiki/Hydraulic_machinery