What is Absolute Pressure

Absolute pressure is a measurement of pressure that is referenced to a perfect vacuum as its zero point. In other words, it is the total pressure exerted by a fluid (usually a gas or a liquid) relative to a complete absence of pressure, which is the absence of any molecules or particles in the surrounding space.

Absolute pressure includes both the atmospheric pressure (if it exists) and the pressure generated by the fluid itself. It is typically measured using instruments such as barometers, manometers, or pressure transducers. The most common unit for expressing absolute pressure in the International System of Units (SI) is the pascal (Pa), although other units like pounds per square inch (psi) or atmospheres (atm) are also used in various contexts.

For example, at sea level, the average atmospheric pressure is about 101.3 kilopascals (kPa) or 14.7 pounds per square inch (psi). So, if you have a container of gas at sea level with a pressure gauge reading 150 kPa, the absolute pressure inside the container would be 251.3 kPa (150 kPa gauge pressure + 101.3 kPa atmospheric pressure).

Absolute pressure Example

Certainly! Let’s use another everyday example involving water to explain absolute pressure.

Imagine you’re swimming at the bottom of a swimming pool. You want to understand absolute pressure in this context.

- Absolute Pressure: Absolute pressure is like the total pressure you feel at the bottom of the pool. It includes the pressure from the water on top of you (water pressure) and the pressure from the atmosphere (air pressure) above the water’s surface.

- Gauge Pressure: Gauge pressure, in this case, would be the pressure you feel from the water alone, without considering the air pressure above the pool’s surface.

Now, let’s break it down:

- Absolute Pressure: When you’re at the bottom of the pool, you can feel the weight of the water above you pressing down. This is the water pressure. In addition to that, you also have the atmospheric pressure acting on the surface of the water. Absolute pressure takes both of these pressures into account.

- Gauge Pressure: If you were to measure just the gauge pressure, you would subtract the atmospheric pressure from the absolute pressure. So, if the water pressure at the depth you’re at is, let’s say, 10 pounds per square inch (psi), and the atmospheric pressure is 14.7 psi, then your gauge pressure would be 10 psi (water pressure) – 14.7 psi (atmospheric pressure) = -4.7 psi.

In this example:

- Absolute pressure accounts for the pressure from both the water and the atmosphere, so it’s positive.

- Gauge pressure only looks at the pressure from the water and can be negative when it’s less than atmospheric pressure.

So, when you’re underwater, think of absolute pressure as the total pressure, including the pressure from the water and the air above the water’s surface, while gauge pressure focuses on just the pressure from the water alone, without considering the outside air pressure. This distinction is essential for understanding the forces at play in underwater activities and other pressure-related situations.

absolute pressure formula

The formula for absolute pressure (P_abs) is:

P_abs = P_gauge + P_atmosphere

Where:

- P_abs is the absolute pressure.

- P_gauge is the gauge pressure, which is the pressure measured relative to atmospheric pressure (the pressure of the surrounding environment).

- P_atmosphere is the atmospheric pressure, which is the pressure of the air or gas in the surrounding environment. Typically, this is taken as 101.3 kilopascals (kPa) or 14.7 pounds per square inch (psi) at sea level.

This formula shows that absolute pressure is the sum of the gauge pressure and the atmospheric pressure. It’s used in various applications to account for the total pressure, including both the pressure of the fluid or gas being measured and the pressure of the surrounding environment.

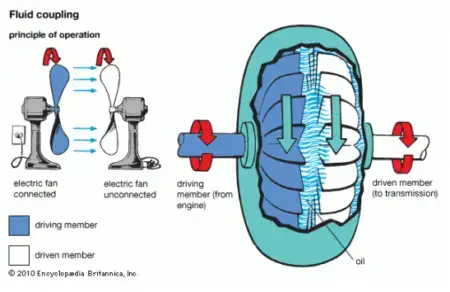

Suggested : Fluid Coupling

Absolute vs gauge pressure

Certainly, here’s a table summarizing the key differences between absolute pressure and gauge pressure:

| Characteristic | Absolute Pressure | Gauge Pressure |

|---|---|---|

| Reference Point | Perfect vacuum (no pressure) | Local atmospheric pressure |

| Zero Point | Typically around 101.3 kPa (sea level) | Local atmospheric pressure at the site |

| Positive and Negative Values | Always positive (includes atmosphere) | Positive when above atmospheric, negative when below |

| Common Use Cases | Altitude measurement, weather forecasting, scuba diving, scientific research, industrial processes where atmospheric conditions are critical | Tire pressure gauges, pressure cookers, industrial processes where atmospheric conditions are not critical |

| Formula for Conversion | Absolute Pressure = Gauge Pressure + Atmospheric Pressure | Gauge Pressure = Absolute Pressure – Atmospheric Pressure |

This table provides a quick reference to the main distinctions between absolute pressure and gauge pressure, including their reference points, zero points, typical use cases, and the formula for converting between the two.

Application of Absolute Pressure

Absolute pressure has several important applications in various fields, including science, engineering, and everyday life. Here are some common applications:

- Aviation: It is crucial in aviation for altimeter readings. Aircraft altimeters measure the absolute pressure at a specific altitude above sea level to determine the plane’s current altitude. Pilots use this information for navigation and safety.

- Weather Forecasting: Meteorologists use absolute pressure measurements to monitor and predict weather patterns. Changes in absolute pressure can indicate approaching weather systems, such as low-pressure systems associated with storms.

- Scuba Diving: Scuba divers use absolute pressure to calculate their depth underwater. The pressure increases with depth due to the weight of the water column above them. Knowing the absolute pressure helps divers avoid decompression sickness and plan safe dive profiles.

- Industrial Processes: Various industrial processes, such as chemical manufacturing and food processing, rely on precise pressure measurements. Absolute pressure is used to control and monitor these processes, ensuring product quality and safety.

- Engineering and Construction: Engineers use absolute pressure measurements when designing and testing systems that involve gases or liquids, like pipelines, boilers, and HVAC systems. It helps them ensure that these systems operate within safe pressure ranges.

- Medical Devices: Medical equipment, such as ventilators and blood pressure monitors, may incorporate absolute pressure sensors to provide accurate readings and control the delivery of gases or fluids to patients.

- Space Exploration: In space exploration, absolute pressure measurements are essential for life support systems and spacecraft design. In the vacuum of space, absolute pressure readings become critical for maintaining a habitable environment inside spacecraft.

- Environmental Monitoring: Scientists and environmentalists use absolute pressure data to study the effects of changes in atmospheric pressure on ecosystems and wildlife. It can also help monitor air quality and pollution levels.

- Research and Laboratories: Absolute pressure measurements are crucial in scientific research, particularly in fields like chemistry and physics, where precise control and measurement of pressure are necessary for experiments.

- Automotive Industry: Absolute pressure sensors are used in modern vehicles for engine control, emission control, and airbag deployment. They help optimize engine performance and safety.

- Oil and Gas Exploration: In the oil and gas industry, absolute pressure measurements are used to monitor and control drilling operations, pipeline transportation, and reservoir management.

- Aerospace Engineering: Absolute pressure is a fundamental parameter in aerospace engineering for designing aircraft, spacecraft, and propulsion systems. It affects engine performance, aerodynamic design, and altitude control.

These are just a few examples of how absolute pressure measurements play a crucial role in various applications across different industries and scientific disciplines. Accurate pressure measurement is essential for safety, efficiency, and the proper functioning of many systems and processes.

Advantages of Absolute Pressure

The advantages of using absolute pressure measurements include:

- Standardized Reference: Absolute pressure is based on a standardized reference point, which is a perfect vacuum. This common reference point makes it easier to compare pressure measurements across different systems and locations.

- Consistency: Absolute pressure readings are not affected by variations in local atmospheric pressure, which can change with altitude and weather conditions. This consistency is crucial in applications like aviation and altitude measurements.

- Safety: In applications where precise pressure control is critical for safety, such as chemical processes or scuba diving, absolute pressure provides an accurate measurement of the pressure exerted by a fluid, ensuring safe operation.

- Accurate Depth Measurement: In underwater applications like scuba diving and oceanography, absolute pressure is essential for accurately determining the depth below the water’s surface, as it accounts for the weight of the water column above.

- Engine Performance: Absolute pressure is used in automotive and aerospace engineering to optimize engine performance. It helps in precise fuel injection, turbocharger control, and air/fuel ratio adjustments for better efficiency and power.

- Meteorology: Absolute pressure measurements are crucial for weather forecasting. Monitoring absolute pressure allows meteorologists to predict weather changes accurately and provide valuable information for disaster preparedness.

- Scientific Research: In scientific experiments and research, absolute pressure is often necessary to maintain specific conditions and obtain accurate data. It helps researchers control variables and ensure the reproducibility of results.

- Space Exploration: Absolute pressure is fundamental in space missions, where there is no atmosphere. It’s used for life support systems, spacecraft design, and propulsion calculations.

- Quality Control: In industrial processes, absolute pressure measurements ensure product quality and safety. They help maintain consistent pressure conditions during manufacturing, preventing defects and ensuring product reliability.

- Environmental Monitoring: Absolute pressure is used in environmental studies to monitor air quality, study the effects of pressure on ecosystems, and measure changes in atmospheric pressure due to pollution or weather patterns.

- Altitude Measurement: Absolute pressure is essential for altitude measurement in aircraft, hot air balloons, and mountaineering. It allows for accurate determination of height above sea level, aiding navigation and safety.

- Oil and Gas Industry: In the oil and gas sector, absolute pressure measurements are vital for reservoir management, well drilling, and pipeline operations, ensuring the efficient extraction and transportation of resources.

- Medical Devices: Medical equipment, such as ventilators and infusion pumps, relies on accurate absolute pressure measurements to provide patients with the right amount of gases or fluids safely.

In summary, the advantages of using absolute pressure measurements stem from their accuracy, consistency, and applicability across a wide range of industries and scientific disciplines. They provide a reliable standard for pressure reference, which is critical for safety, efficiency, and precision in various applications.

Disadvantage of Absolute Pressure

While absolute pressure measurements have many advantages, they also come with certain disadvantages and limitations:

- Complexity of Understanding: Absolute pressure can be more challenging for individuals to grasp compared to gauge pressure (pressure relative to atmospheric pressure). Understanding the concept of pressure referenced to a perfect vacuum can be less intuitive.

- Cost: Instruments capable of measuring absolute pressure tend to be more expensive than those measuring gauge pressure. This cost difference can be a factor in budget-sensitive applications.

- Zero Value: Absolute pressure is always positive because it is referenced to a vacuum. This means that even when the pressure is close to zero (as in a near-vacuum environment), the absolute pressure reading will not reflect this, potentially making it less informative in such situations.

- Lack of Context: Absolute pressure does not provide information about changes in atmospheric pressure, which can be important in some applications, such as weather forecasting and aviation. Gauge pressure readings include this context.

- Limited Use in Some Contexts: In certain industries and applications, gauge pressure is more relevant. For example, when assessing the performance of pressure vessels, piping systems, or hydraulic systems, gauge pressure (which considers atmospheric pressure) is often preferred.

- Increased Complexity in Calibration: Absolute pressure instruments require careful calibration because they must account for variations in local atmospheric pressure. Gauge pressure instruments are typically easier to calibrate because they reference the local atmospheric pressure.

- Less Intuitive Readings: In everyday scenarios, gauge pressure can provide more intuitive readings. For example, a tire pressure gauge that reads “32 psi” is easier for most people to interpret than an absolute pressure reading of approximately 46 psi (assuming atmospheric pressure is 14.7 psi).

- Application-Specific: Absolute pressure is not suitable for all applications. For tasks where the interaction of a fluid with the surrounding atmosphere matters (e.g., pressure cookers), gauge pressure is more relevant.

- Conversion Complexity: When working with both absolute and gauge pressure measurements, converting between the two can introduce complexities and potential errors if not done correctly.

- Maintenance Considerations: In some environments, particularly those with variable atmospheric pressure or extreme conditions, maintaining the accuracy of absolute pressure measurements may be more challenging and require additional calibration and corrections.

It’s important to choose the type of pressure measurement (absolute or gauge) based on the specific needs and context of the application to ensure the most appropriate and accurate results. Each type has its advantages and disadvantages, and the choice depends on the requirements of the task at hand.

Reference : https://energyeducation.ca/encyclopedia/Absolute_pressure